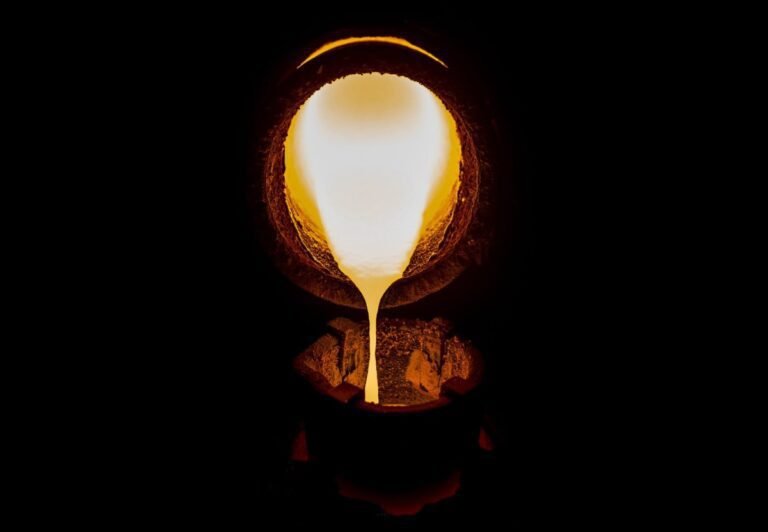

People have been casting metal parts in the same basic way for thousands of years: pouring molten metal into a mold, often made of compacted sand and clay.

There’s a reason this ancient method is used today: Sand casting is cheap and works well with both ferrous or iron-based metals and non-ferrous metals. But there is one wasteful downside. The technique requires more metal than the finished part needs, and while the scrap is usually recycled, melting the excess metal again and again consumes energy. 3D printing has emerged as an expensive alternative generally reserved for low-volume prototypes and parts.

A startup, Magnus Metalis working on a metal casting technology that it claims is as fast and energy efficient as 3D printing at a cost that can rival sand casting.

“Over time, as the reliability and usage of the machine increases, I think we will be competitive for parts that are not very simple,” Magnus Metal co-founder and CEO Boaz Vinogradov told TechCrunch.

For simple parts, sand casting will still have the advantage, but for complex parts like gearboxes, Vinogradov is confident his company can compete on cost.

To make these parts, Magnus Metal borrows elements of sand casting and 3D printing to perform what it calls digital casting. Before casting operations begin, the company’s software divides a design into layers. The company then takes the negative of that shape and creates ceramic molds between four and 20mm thick, which will hold the metal in place while it cools.

In the casting machine, the metal melts and drips onto the ceramic base. Once a layer is complete, more metal is added. Each successive layer melts the previous one, ensuring the layers are connected while also allowing impurities to float to the top, Vinogradov said. Melting and blending the layers allows its parts to have lower defect rates and are 10% to 20% stronger than traditional cast parts, the company said.

Magnus Metal plans to sell its machines to customers as well as the proprietary ceramic used to produce the bases. The goal, Vinogradov added, is to generate $500,000 to $1 million in recurring revenue per machine.

“If you’re only selling machinery, you’re going to be circular,” he said. “We produce our own ceramics, because to create a layer, you need ceramics that can withstand the impact of molten metal many times.”

Magnus Metal’s layer-by-layer technique is similar to 3D printing, but Vinogradov said his company’s approach is faster, which helps keep costs down. Each ceramic base can also be reused, though only for a finite number of components. And unlike 3D printing, which typically requires specific raw materials, Magnus Metal said its system can use materials specified by the customer.

The method does not require expensive tooling to create the bases, unlike sand casting molds, according to Magnus Metal. That means customers can make parts more cost-effectively in lower volumes than traditional casting, the startup says.

Building industrial machinery like this doesn’t come cheap, which is why Magnus Metal has raised a $74 million Series B round, according to TechCrunch exclusively. The round was led by Entrée Capital and Target Global with participation from Awz Ventures, Caterpillar Ventures, Cresson Management, Deep Insight Ventures, Discount Capital, Essentia Venture Capital, Lip Ventures, Lumir Ventures, Next Gear Fund and Tal Ventures.

“This [round] it’s going to take us to industrialization this year and beta testing early next year,” said Vinogradov. “The goal is to use this funding to have an industrial machine that is robust enough that customers have completed testing.”