Three years ago, as the pandemic caused the chaos for large and small companies, the chief officer of the Colgate-Palmolive Luciano Sieber supply chain was orchestrated a “logistics blitz”.

The result gave Sieber a better understanding of how Colgate-Palmolive moves its products around the world. But he stayed sieber with another problem: too many data.

About a year ago, Sieber says he found a solution to this problem with Uber Freight. The long-term Logistics and Analytics arm of the Ride-Hailing service has developed new ways to protest large amounts of data using artificial intelligence. Colgate-Palmolive has become one of the first companies to use one of its newest products, an LLM Uber Foright to focus on logistics calls AI.

Now, Uber Freight is more formally launching a series of AI features to loaders around the world as part of existing supply chain software. This includes an extension of AI ideas, which Uber Freight started quietly in 2023as well as more than 30 AI agents built to “perform basic logistics tasks throughout the life cycle of goods”.

Uber Freight is not only trying to bite discouraging supply chains with modern artificial intelligence tools. Flexport has announced its own series of AI tools in February and there are a myriad of newly established businesses trying to help companies protest, reduce stocks and better predict supply and demand.

But Uber Freight bets that AI solutions can have a direct impact on the bottom line of both blue chips customers and about 10,000 other loaders with whom she works with. This is largely due to the knowledge and relationships it has established in eight years since it was created To match the trucks with distant shipments with loaders.

“The supply chain is inherently a problem rich in data. It is complicated, it is separate and AI can serve a fundamental role in its formation and acceleration,” said Uber Freight Lior Ron in an interview with Techcrunch.

‘We have built at the moment“

Uber Freight began as a simpler brokerage model when it started in 2017, but Uber’s subsidiary has steadily evolved over the years to a service provider to companies carrying goods around the world.

Many modern companies are trying to find ways to incorporate artificial intelligence (often in mixed results) It should not be surprising that Uber Freight is setting the front and center of technology. After all, both Ron’s undergraduate work and his postgraduate dissertation focused around the AI - back “at dark ages when he was called” neural networks “, he jumped.

Ron continued to work with mechanical learning technology when running Google Maps from 2007 to 2016.

“This species led me to the fundamental belief, nine years ago, that the supply chain is fundamentally a first, first technological challenge that could be accelerated with data connectivity and over time, AI,” he said. “We’ve built on this moment. I think, since I started Uber Freight.”

Ron said Uber Freight used mechanical learning in his work from the beginning. But it was about two years ago that the team started trying to work with more advanced AI genetic capabilities.

This “was not an easy road,” Ron said. Uber Freight’s initial attempts to build a “co-supply pilot” kind were full of illusions and returned accurate answers only about 60% to 70% of the time.

Now that technology has been “tested battle” and “real business results”, with a accuracy of 98%, according to Ron. The company says the AI Insights model has been trained in internal and external data associated with the $ 20 billion -billion load that helps in traffic every year. It also utilizes multiple models of “that provide optimum combinations of price, precision and performance”, according to Uber Freight.

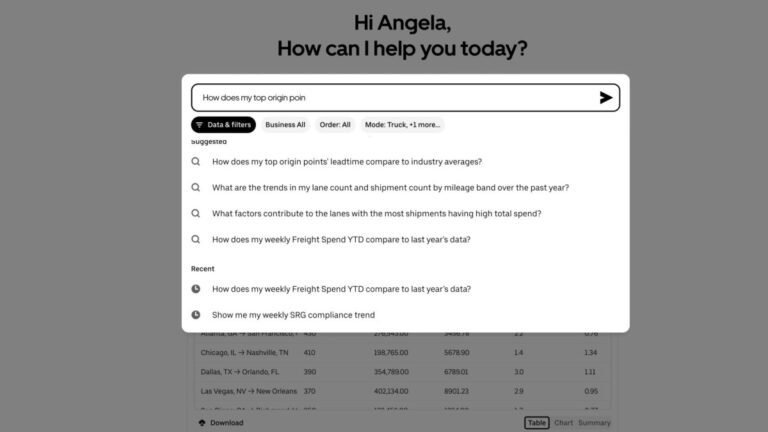

Ron said that this push AI creates new ways for customers to work with the data related to their supply chain. They can ask AI to quickly pull, for example, the worst points of origin for specific missions. Or they may request that all shipments be displayed in CVs in 2023. ” Ron stressed that the questions can be much more complicated than this, and the model always goes on.

AI is presented to customers as well as other popular LLM interfaces. He will also show his work and make it clear where all the data comes from, as well as other models of reasoning.

All of this allows a customer to “gain information on your network much faster, about 100% accuracy immediately, compared to the configuration of what you want to learn, sending some analysts and waiting for two weeks to present PowerPoint to return to discuss,” Ron said.

“What do you want to learn?“

Uber Freight works with many Fortune 500 companies, but has found a very willing collaborator at Colgate-Palmolive to try out AI ideas and other new tools. The band is already making a series of AI models available to all its employees, according to Sieber. It also makes workers receive a compulsory training for the morality of the AI developed at home.

“I think it is great. Because it turns the conversation from fear to, ‘how it makes me more effective and how [do] I become a better professional and deliver more with the access and use of these new technologies, “Sieber said.

For example, Sieber said his company had used AI to easily identify carriers who receive fewer missions than they are conventionally obliged to move. From there, they can find because these levels are low and either end up with one solution to get the carrier back in compliance or leave them in favor of another.

This was previously a challenge to solve in real-time resolution, Sieber said because companies such as Colgate-Palmolive work with thousands of carriers. Each of them can operate with different systems and workflows and all this information that has ever emerged was not really centrally managed.

The next step with AI, both Sieber and Ron, have found ways to create more preventive solutions. Ron said this is another place that Uber Freight can bend the strengths of his data. “We know the facilities. We know the strips. We know the prices,” he said. “What do you want to learn?”

These more preventive consolidations come in the form of alerts that say to a customer such as Colgate-Palmolive that pay on certain routes or that there are faster options for a particular mission.

Any single proposal can only save a few hundred, or maybe a few thousand dollars. But concentrated throughout the network, it could make a big difference.

That is why, when asked, Sieber hastened to reply that Colgate-Palmolive’s chief financial director is the executive who is more pleased with what Uber Freight was activated. “He likes to see the logistics cost decrease,” Sieber laughed.