Bio again he says his modified bacteria are currently eating about a ton of CO2 per day.

Discovered by researchers at the Technical University of Denmark, Again Bio is testing its hungry microbes on exhaust gas from a sewage treatment plant in Copenhagen. The startup is 2.5 years old and quietly raised a $10 million seed round in February from ACME Capital, GV (formerly Google Ventures) and Atlantic Labs. The company also benefits from a nearly $47 million (€43 million) grant that Horizon Europe awarded to a project using Again’s technology, PyroCO2.

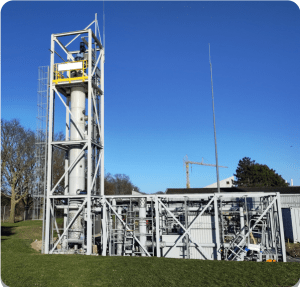

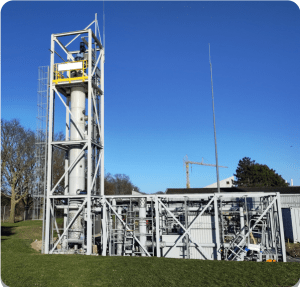

Again the whole point is to funnel industrial exhaust into a 65-foot-tall bioreactor, where its bacteria feed on climate pollution and hydrogen and secrete a useful byproduct: vinegar. The startup says it refines this byproduct into acetic acid and acetate — base chemicals for things like detergents, paints, pharmaceuticals and textiles. Again’s point-source carbon sequestration service is free because its job is to sell production.

Image Credits: Bio again

At the Copenhagen plant, Again says the fermentation vessel is currently operating in a sort of trial mode, allowing the startup to sample the resulting chemicals. However, co-founder and CEO Torbjørn Ølshøj Jensen told TechCrunch that Again has a contract with an undisclosed customer that is “big enough that our focus is really just on building factories and getting them out there.”

Jensen added that the technology is now “producing at yields that are commercially viable.”

The company declined to say more about the deal, which apparently drives its expansion into Europe and North America.

“It’s really dirty stuff that we’re working with,” co-founder and COO Max Kufner told TechCrunch, “but the cool thing about these bacteria is that they feed on them. […] and continue to be developed to address potential inhibitors present in the gas.”

In addition to genetically modifying bacteria, “a lot of the work we’re also doing is forced evolution,” Kufner explained.

Again it aims to help rid industrial facilities, but the startup relies on hydrogen produced from fossil fuels to power its specialized bacteria. According to Jensen, the startup’s chemical production can be “carbon neutral” using it gray hydrogen because Again can capture CO2 from hydrogen manufacturing edit, process. Regardless, the methane industry, which fuels gray hydrogen production, is a serious problem for the climate. Jensen added that Again plans to use green hydrogen — made through electrolyte and renewable energy — in the future.