Found Energy doesn’t have the typical startup origin story: It started with a space robot that supposedly ate itself. Now, the company is developing the same technology to power aluminum foundries and long-distance shipping.

Almost a decade ago, Peter Godart, Energy foundIts co-founder and CEO was a scientist at NASA’s Jet Propulsion Laboratory. He and some colleagues figured out how to power a probe that could visit Jupiter’s moon Europa. The group was discussing the energy density of batteries that might be suitable when a stray thought landed in Godard’s head. The aluminum used to build the spacecraft held more than 10 times the energy of any state-of-the-art battery. Why not use the parts of the spacecraft to power itself?

“They gave me a bunch of money to start a program that I lovingly called the self-cannibalizing robot lab,” Godard told TechCrunch. “We looked at giving robots the ability to consume their scrap aluminum for fuel.”

But as he continued his research, Godard had second thoughts. “I had a moment when I realized that my time would be better spent solving Earth’s problems,” he said. His timing couldn’t be better. Congress cut some of the funding for the Europa missions, and JPL allowed Godard to transfer the intellectual property to MIT where he continued to work on the problem during his Ph.D.

For Godard, aluminum had several obvious advantages: It is the most abundant metal in the Earth’s crust, it can store twice as much energy per unit volume as diesel without being volatile, and it is possible to recover up to 70% of the original electrical energy as heat. used for smelled. “I was like, oh my god, we’ve got to do something with this,” he said.

To release the energy embodied in refined aluminum, Godard had to figure out how to overcome the metal’s defenses, so to speak. “If you drop a piece of aluminum in water and try to oxidize it using water, it will take thousands of years,” he said.

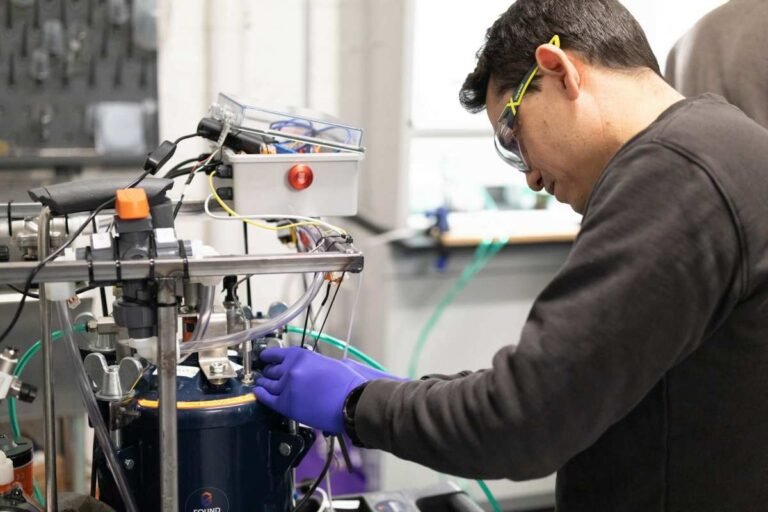

Godard’s process is much, much faster. Once water is dropped on aluminum coated with a Found Energy catalyst, the surface of the metal quickly begins to bubble as the reaction releases heat and hydrogen gas. Within seconds, the aluminum begins to expand as the hydrogen bubbles cause it to flake off. This allows the water to further penetrate the metal, repeating the process over and over again until all that is left is a gray powder. “We actually call it fractal exfoliation,” Godard said.

Found Energy collects the resulting steam and hydrogen, each of which can be used for a range of industrial processes. “One of the most difficult elements of heavy industry to carbonize is heat,” Godard said. “And now here we have this really flexible way of delivering heat over a very wide range of temperatures, from 80 to 100 degrees Celsius all the way up to 1,000 degrees Celsius.” In total, approximately 8.6 megawatt-hours of energy can be recovered per metric ton of aluminum.

What remains is not a waste either. The catalyst can be recovered and the powder is aluminum trihydrate, which can be melted down once more to create metallic aluminum. Any impurities, including food waste, plastic soda can liners, and mixed alloys, remain larger than aluminum trihydrate powder and can be easily filtered out.

“All of these things work in our process because our catalyst just eats aluminum and essentially leaves everything else untouched,” Godard said.

Found Energy recently raised a $12 million oversubscription, according to TechCrunch exclusively. Investors in the round include the Autodesk Foundation, GiTV, Glenfield Partners, Good Growth Capital, J-Impact, Kompas VC, the Massachusetts Clean Energy Center and Munich Re Ventures.

When using aluminum scrap, which is Found Energy’s original design, the process is carbon negative. The startup is targeting industrial heat in its go-to-market strategy, but Godart also sees applications in marine shipping and long-haul transportation. Aluminum is slightly heavier than diesel or fuel, but its energy density could be a game changer for these industries.

One could imagine future aluminum-powered ships dumping their waste dust in a smelter to refuel for a return trip. “Just sip a little bit of that energy as you go, and then you’ve essentially found a new fuel for marine shipping as well,” he said. “In a strange way, we are renewing the concept of solid fuel.”