In 2014, investor and entrepreneur Peter Thiel infamously drew the distinction between companies that deal in “people” versus those that deal in “bits.” In its crudest terms, the first category includes businesses that focus on things like hardware and manufacturing. the latter, software and financial services. Just 10 years later, the distinction now seems quaint, if not entirely irrelevant.

In the last five years or so, a new group of startups has emerged. In some ways, they’re more like 1950s Silicon Valley than 2010s: Eschewing Thiel’s distinction entirely, they generally see pieces and people as essentially impenetrable, two hammers to hit the same nail. Few startups embody this new paradigm better than Individual Industries.

Four-year-old Atomic is trying to automate the manufacturing of tools and dies, a critical step in making a wide range of consumer and industrial products, from fasteners to aircraft parts. The project is ambitious in the extreme — some injection molds are extremely complex, with tool and die makers acting almost as alchemists turning lead into gold. Furthermore, each product is unique and requires the exact kind of generalizable intelligence that humans have perfected over thousands of years of evolution.

But tool and die manufacturing is strictly limited by the geometry of the customer’s product: In this way, alchemy is well-suited to solving machine- and physics-driven problems. Just as tool and die markers earn their stripes over a period of many years, Atomic is designing an AI software stack that can become a highly efficient tool and die design engine, almost like a translation layer between what it wants to manufactured by the customer and the tool that will manufacture it.

“In my estimation, the world of atoms is worth 100 times more than the world of bits as an industrial (and soon space) society,” said Atomic CEO and co-founder Aaron Slodov. “It is also orders of magnitude more difficult and expensive to innovate. We are beginning to see how some of the most valuable companies on Earth are so valued for the intersection of technology and people. Pushing the world of atoms toward the same pace as the world of bits is vital.”

“AI in the world of individuals”

At its core, Atomic’s applied AI software stack is analogous to training a human. Imagine a new apprentice. “You start and you’re basically a liability,” Slodov said. But over time, that apprentice goes from a liability to an asset. from student to teacher. But the thing is, people, even well-educated ones, are rarely 100% accurate in their estimations.

Atomic, founded in 2019 by Slodov, Austin Bishop and Lou Young Jr., wants to build something better. First, the company starts with individual areas of mold design that can be rigorously tested against industrial simulation tools. Additionally, the startup is essentially working with products that are in the final stages of design — the Design for Manufacturability (DFM) process is essentially complete. (The ultimate goal is to move up and work directly with product designers, who could get near-real-time feedback on their product design.)

The software competes internally with human teams, and the company collects every bit of data from the factory to compare the tool to what the customer wanted. Ultimately, Atomic wants to create an AI that can generalize the problem: “One day, it will learn how to optimize every design in terms of cost, manufacturing complexity, lead time, and performance — just like the best tools and mold makers on Earth now,” Slondoff said.

Oh, you want to save America by augmenting the industrial base with AI-powered factories? perfect for me too

— Aaron Slodov (@aphysicist) August 29, 2023

Investors — particularly those focused on hard tech and the VC arms of big automakers — are taking notice. The company closed a $17 million seed round led by Narya, with participation from 8090 Industries, Acequia Capital New Industrials, Porsche Ventures, Yamaha Motor Ventures, Toyota Ventures and Impatient Ventures, and backed by Phaedrus, SaxeCap, Zack Nathan, Tyler Knight and the CWRU Alumni Fund. Narya partner Falon Donohue joins Atomic’s board of directors.

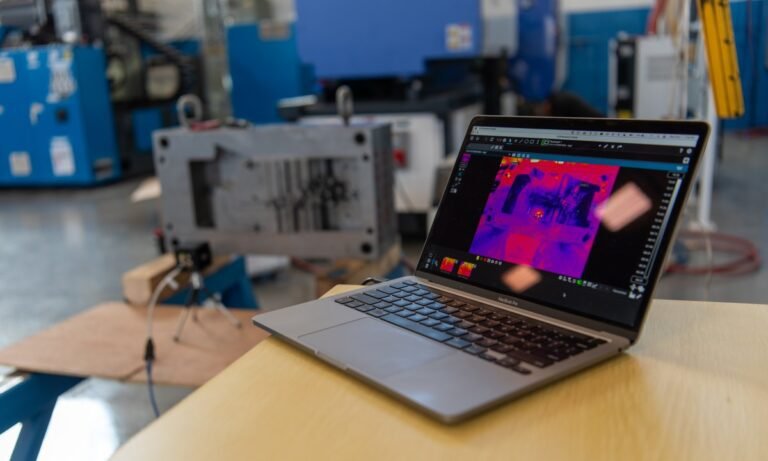

The new funding comes just over 18 months after the company raised $3.2 million pre-seed. (Atomic was also part of Y Combinator’s W21 cohort.) With the new funding, Atomic created a state-of-the-art test facility in Detroit to develop its AI manufacturing capabilities.

While the Midwest isn’t exactly the sexiest region for startups, as Slodov put it, “the best talent in tool making is in the Midwest. [and] we lean heavily into that DNA.”

Beyond the new square footage, Atomic will use the money to increase the number of employees in software, operations and manufacturing — and to build a supercomputer. The startup does so much high-performance computing and machine learning computing that it’s actually cheaper to build in-house than to outsource to services like AWS, Slodov explained.

Atomic’s designs are focused on the specific, highly skilled trade of tooling and mold making. Conceptually, however, the startup seeks to accelerate a new future for America’s industrial base. The risk is huge, but the reward will likely be even greater.

“Imagine factory workers having productivity multipliers like software engineers (and competing as well),” Slodov said. “So we’re throwing technology at it, maximizing human productivity and creating a new industrial base that can propel us into the future.”

“Imagine if you could build factories that could mass produce anything, at a fraction of the speed and cost. What would you build? Where would you build?’