If CES is anything to go by, 2024 is shaping up to be a great year for makers and hobbyists. I enjoyed getting a closer look at Rownd, but it wasn’t even close to being the only lightweight company showing off cool stuff at the Las Vegas trade show. Coast Runner, a newcomer to the desktop CNC milling industry, promises to make the technology accessible to everyone from professionals to hobbyists. Coast Runner breaks down the barriers of traditional CNC milling with an emphasis on power, compact size, and most importantly, training.

TechCruch spoke with Tyler Hoeft, who wears many hats at the company, from marketing to inventory management, and believes that the lack of educational resources and community forums in the CNC space has significantly hindered potential users. To address this, Coast Runner is committed to providing comprehensive video tutorials and creating a discussion forum for users to share information and collaborate on plans. In addition, Coast Runner is developing a bounty board system where users can pay others to create blueprints or mill parts if they lack the necessary skills. I think it’s a great idea, mainly because milling and turning is a little different to 3D printing – as any old, wrinkled engineer will tell you, toolpaths, feeds and speeds are as much art as science.

The Coast Runner machine aims to be both economical and powerful.

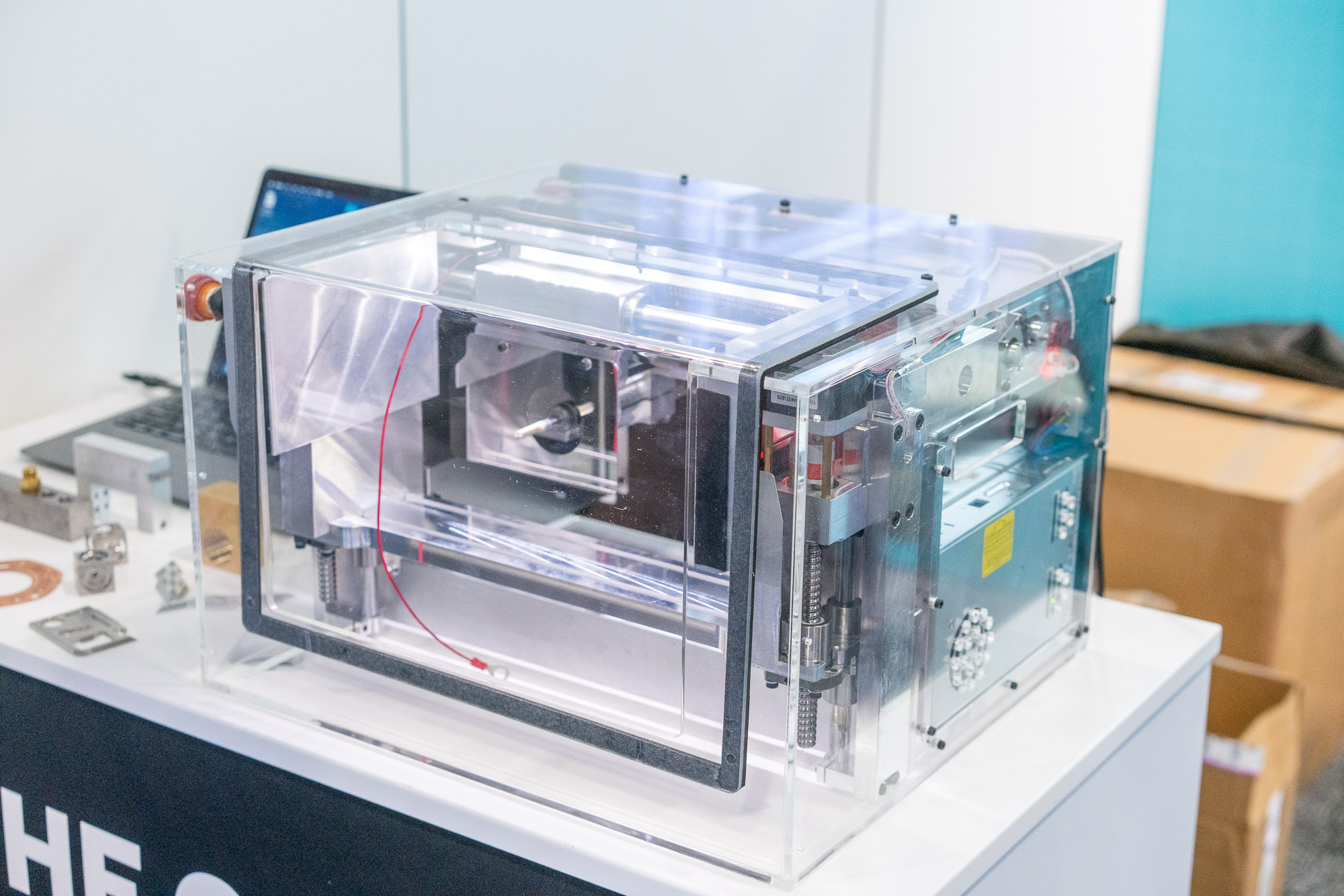

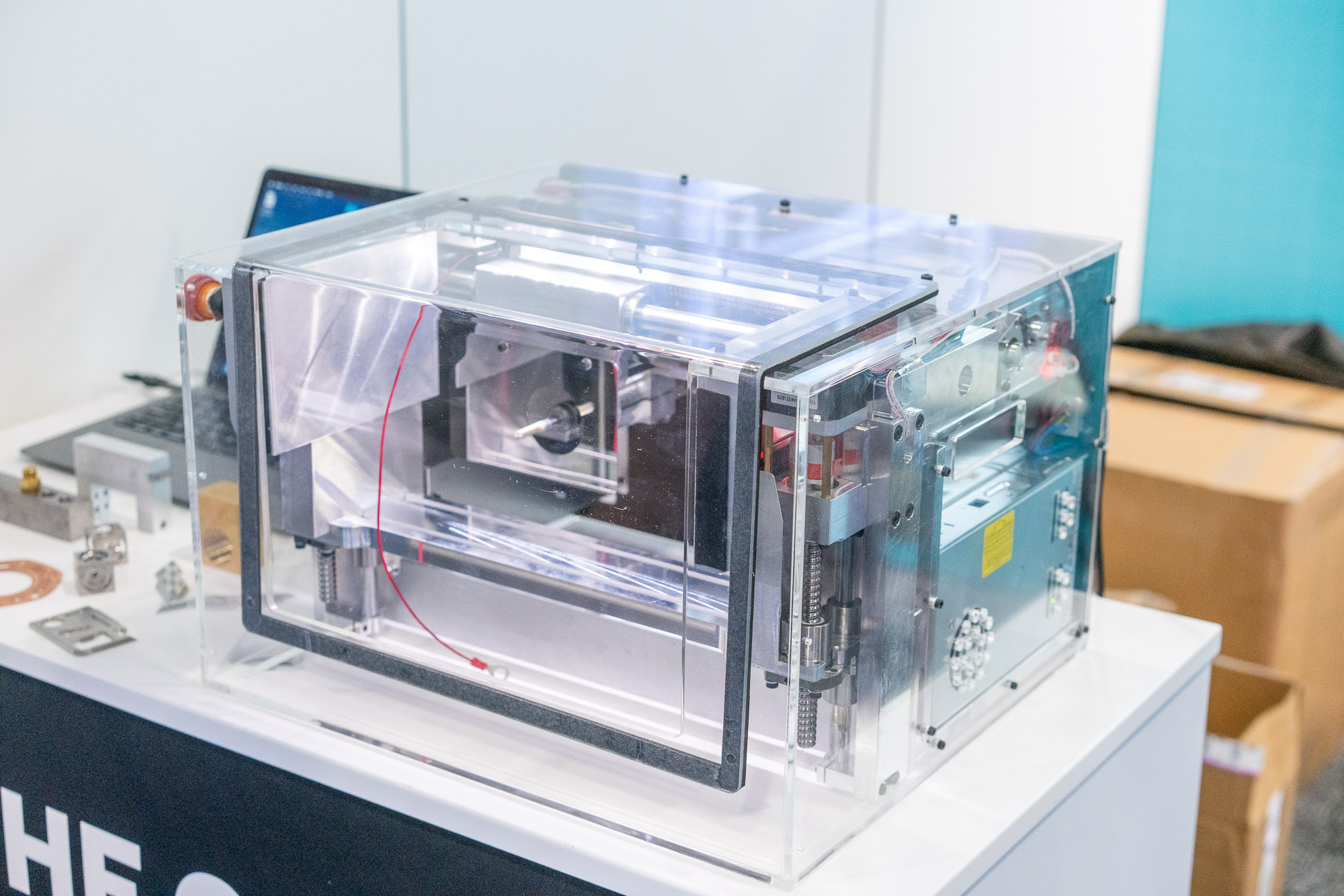

Coast Runner put one of the machines in a transparent case for CES purposes, showing off its innards. The company manufactures many of the components itself. Image Credits: TechCrunch / Haje Kamps

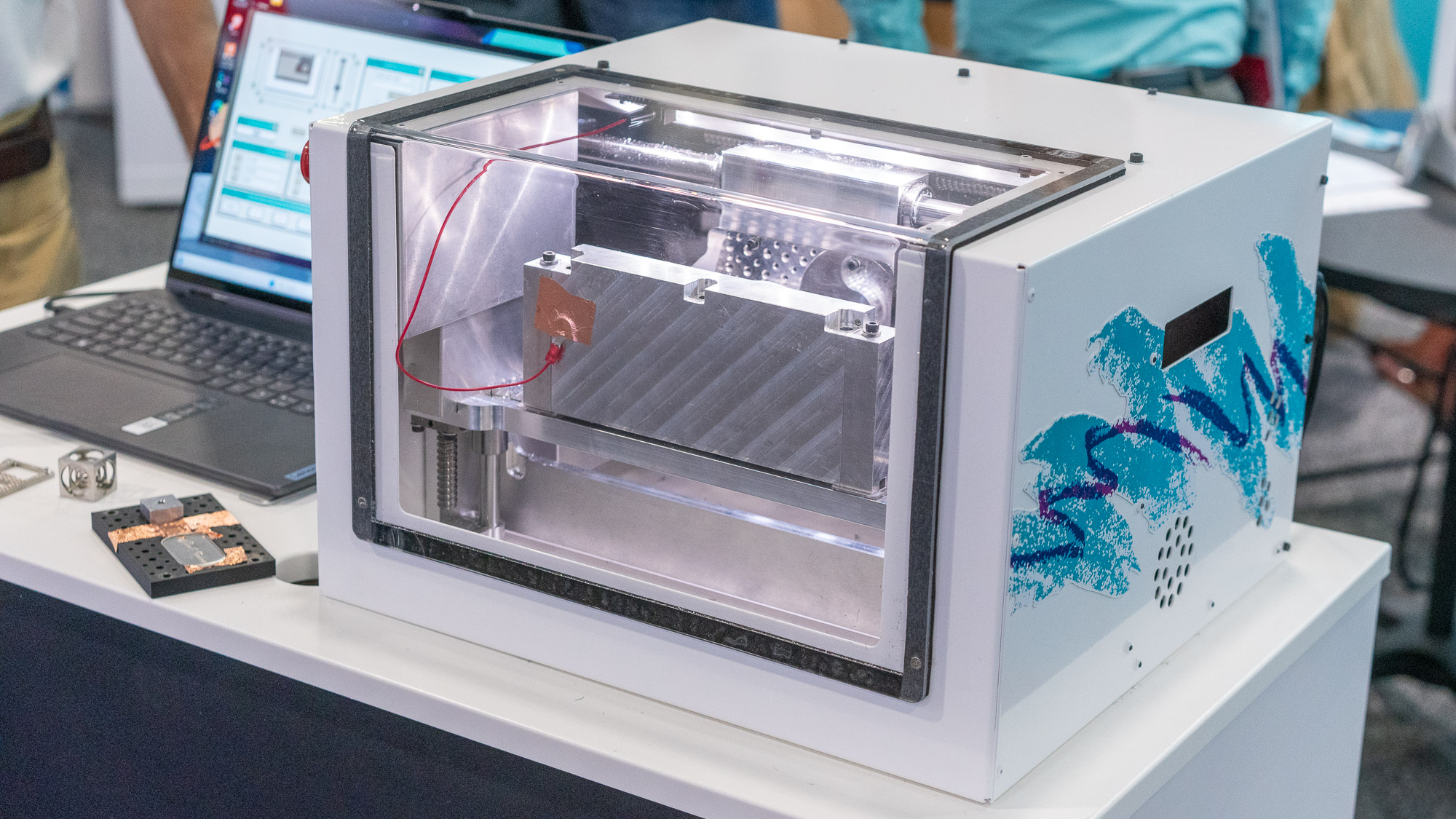

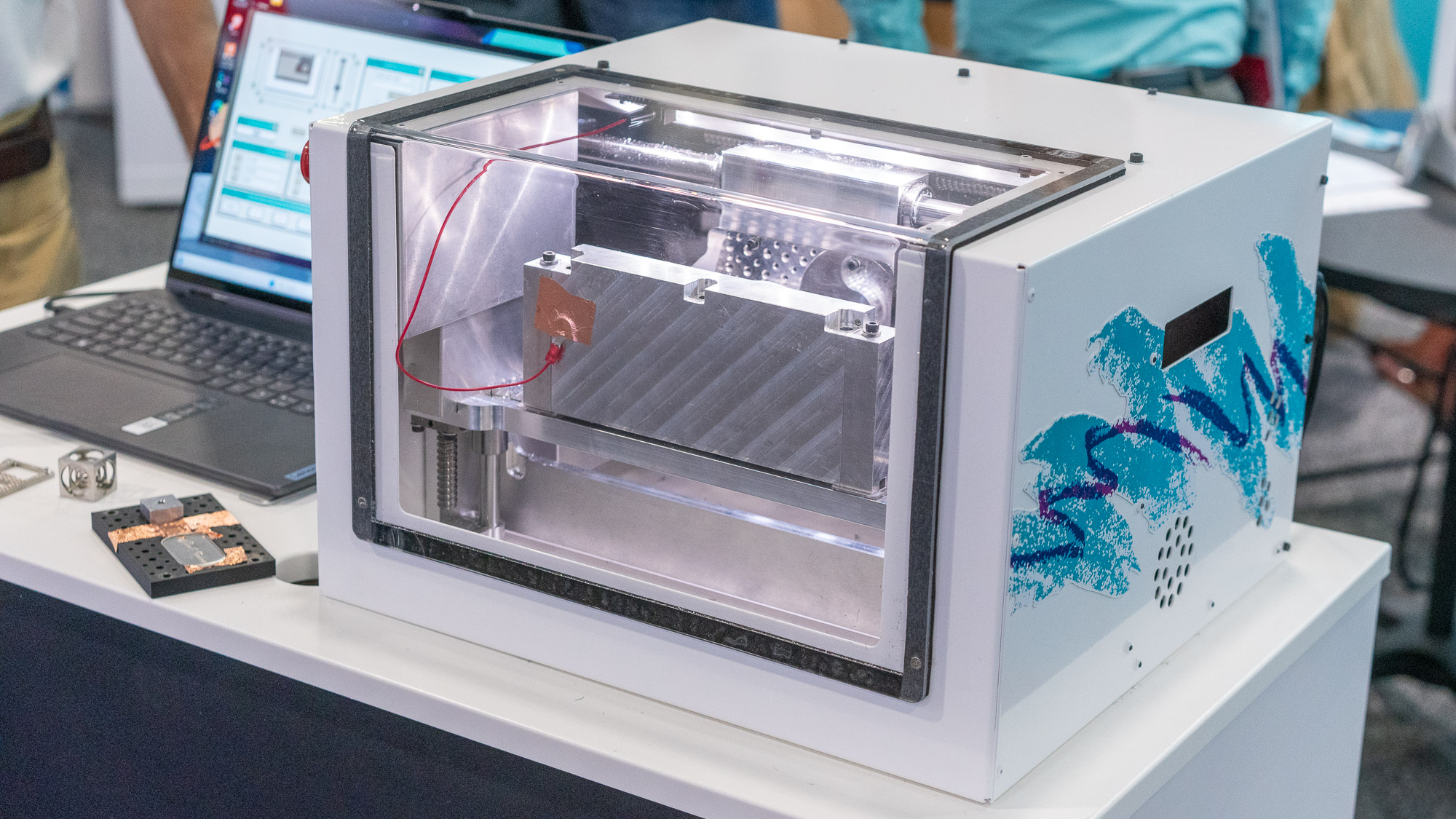

“We build one of the most powerful desktop CNC machines you will find on the market. You can cut everything up to titanium. Anything softer is possible: Plastics, brass, hard steel, aluminum, everything,” says Hoeft. “You have to change tools manually — our main focus was to get the price low enough for people who want to dip their toes in, or for people who want to build and have four or five of these machines to make small parts for their business.”

Despite its power, the machine is compact and lightweight, weighing only 42kg and fits comfortably on a single desk, making it an interesting choice for small businesses or hobbyists.

Perhaps the most exciting feature in the works is that the company is working on AI-powered modeling features. This advancement aims to make modeling a point-and-click process, significantly reducing the learning curve for new users and increasing the appeal of CNC milling to a wider audience.

Personally, I love the retro 1990s takeaway cup inspired design. Don’t let the retro design fool you, though — there’s a lot of 2024 tech in there. Image Credits: TechCrunch / Haje Kamps

In an industry dominated by several big players (Makera’s $6,000 Carvera and $7,000 machine from Bantam Tools are probably its closest competitors), Coast Runner’s relentless focus on customer education and powerful, compact CNC machines make it an interesting entrant to the market.

“Most companies in this space are content to sell their machines and wish their customers the best of luck,” shrugs Hoeft. “We are committed to guiding its users from the initial idea to the final product.”

Coast Runner is a name to watch as it launches its Kickstarter campaign with a price tag of $2,400 next month. The final retail price will likely be around $3,000, the team tells me.