While many robotics companies build human -sized robots or work to automate entire factories, Petite On the contrary, he is trying to think great with the construction of young.

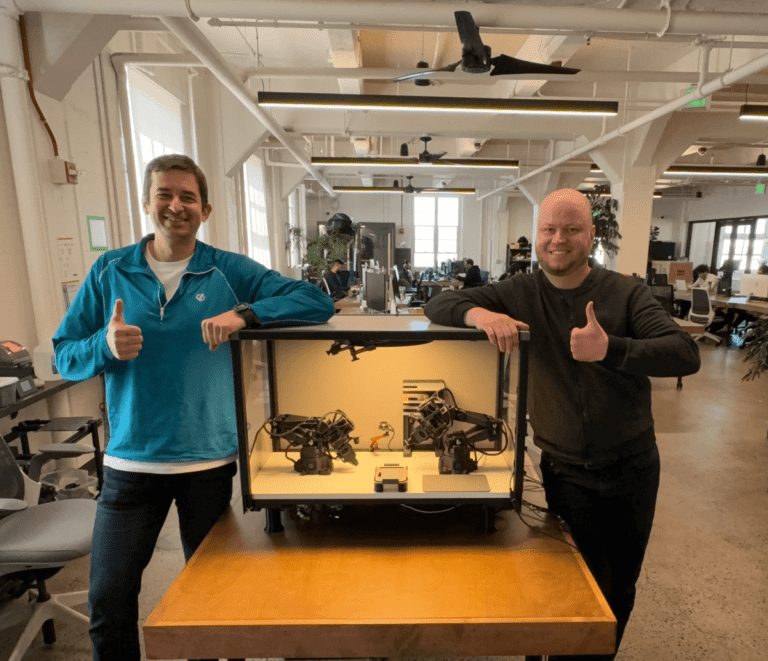

The San Francisco -based microfactory created a general purpose kit, which is about the size of the Siberian dog box of Husky. This compact factory includes two robotic weapons and can be trained with human demonstration as well as through AI.

‘General -purpose robots are good but not necessary [to] Be Humanoid, “said Igor Kulakov, co -founder and chief executive of Microfactory, in an interview with TechCrunch.

Instead of selling individual robotic weapons, the microfactory system comes as a closed but transparent workstation, allowing users to monitor the real -time manufacturing process. The compact factory-in-a-box is designed for accuracy work such as circuit board assembly, adhesion adhesion and cable launch. Users can train robots with naturally guiding weapons through complex movements-a practical approach that Kulakov says it works faster than traditional AI programming for complex production sequences.

“It usually takes two hours, but in this way, the robot understands much better what to do,” Kulakov said. “When you hire people, we still have to spend time, like a week or something, guide these people to supervise their work.

Kulakov’s experience with traditional construction helped trigger the idea behind microfactory.

He and his co -founder, Viktor Petrenko, used to run the bitlighter, a production business that made portable lighting equipment for photographers. Kulakov said it was difficult to train new employees on how to complete the construction process properly. When developments in AI seemed to automate this type of work, they decided to jump the opportunity.

TechCrunch event

Francisco

|

27-29 October 2025

Kulakov and Petrenko started the microfactory in 2024. It took them about five months to build their original. The company now has hundreds of premeditations from customers who want to use machines for various applications, including assembly of electronics and even the processing of snails that will be sent to France for Escargot.

Microfactory raised just $ 1.5 million pre-spades for funding including investors such as AI executives who hugged the face and investor-business navy Ravikant. The round estimates the young start in a valuation after a sum of $ 30 million.

Kulakov said the company plans to use funding to build and mission of its units. The company is currently turning the original into a commercial product that hopes to start shipping in about two months.

The company also plans to make some recruitment and continue to improve its technology, including AI models running under the hood.

“Our development is related to material building, so we set the goal of increasing 10X every year,” Kulakov said. “In the first year, we want to produce 1,000 robots, [about] Three per day, and we have the ability to do this. Then, [we want to] Make more and more productions. ”