Verve Motiona startup that makes a robotic “outfit” designed to help workers complete physically demanding tasks in factories and other similar environments, announced today that it has raised $20 million in a Series B round led by Safar Partners with participation of Cybernetix Ventures, Construct Capital, Pillar VC, OUP and angel investors including Okta co-founder Frederic Kerrest.

The new cash, which brings Verve’s total to $40 million, will be used to expand Verve’s market share and production efforts, Verve co-founder and CEO Ignacio Galiana said in an email interview with TechCrunch.

“Verve is pioneering a new category of connected wearable technology for the industrial sector by integrating robotics into functional clothing,” said Galiana. “The wearable robotics category is a relatively new industry and, like any emerging category, faces the task of raising awareness and building a compelling case of need in the workplace.”

Verve’s origins lie in the Harvard-run bioengineering lab at the Wyss Institute and School of Engineering and Applied Sciences. There, as part of a DARPA-funded initiative with support from the National Science Foundation and the National Institutes of Health, Verve’s co-founders — Galiana, Conor Walsh, Mike Rouleau, Nathalie Degenhardt and Nicolas Menard — developed technology to mitigate fatigue and injuries. risks to military personnel.

DARPA’s Web Warrior program focused on technologies that could help soldiers lift 100kg loads. But Galiana realized applications far beyond combat. Galiana launched Verve in 2020 to commercialize his and his team’s technology for industrial, retail and manufacturing settings.

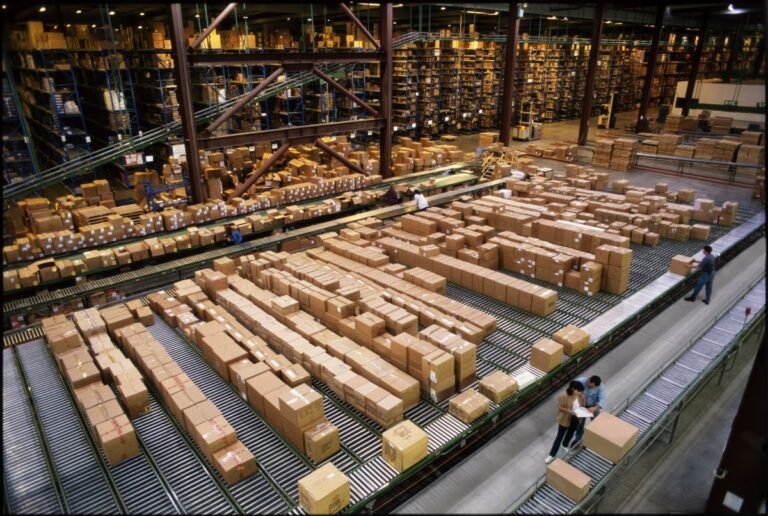

“In many warehouses and fulfillment centers, the average worker often lifts up to 50,000 pounds a day during hundreds of tasks and movements,” Galiana said. “These repetitive, labor-intensive operations… [can] they result in overwork, injuries, fatigue, loss of productivity and high employee turnover. Verve’s mission is to power the human workplace through human-centric robotics.”

Verve’s powered suit adapts to workers and tasks and is meant to be worn like a regular backpack. It is equipped with sensors that automatically register “dangerous” movements, such as excessive bending and twisting, in addition productivity metrics such as number of lifts, hours of use and weight unloaded.

Image Credits: Verve Motion

The way Galiana sets it up, the exosuit’s selling point is threefold: It mitigates the risk of injury. boosts productivity. and is more practical than “passive”, unpowered alternatives or bulkier, rigid exoskeleton designs.

“For the C-Suite level manager, reducing injuries and fatigue not only leads to a happier and healthier workforce – it also reduces worker’s compensation and injury payments while helping to retain talent,” Galiana said. “Because users are less tired, overall productivity increases.”

Me, I’m not so sure that the average warehouse or warehouse operator will happily spend thousands to tens of thousands — or even hundreds of thousands — of dollars to outfit their entire workforce with outerwear. There is also the concern about privacy on the part of the employees. Sensors tracking your every move sounds like a recipe for mission creep. Add to that the fact that exosuits like Verve’s haven’t been studied for long-term (10+ year) effects on workers — and the fact that Verve has stiff competition in its class from Germany’s Bionic, Ottobock’s SuitX and ReWalk .

But — to Verve’s credit — the Cambridge-based company, which has 40 employees, has managed to sell about 1,000 take-outs so far and has pilot programs with chains including Albertsons and Wegmans.

“The challenge [we face] is to convey that the goal is to create a safer and more efficient future for industrial workers,” Galiana said. “As we raise awareness of the benefits of a soft suit, we anticipate a rapid transition to a future where wearable robotic technology seamlessly blends into our everyday work attire.”

Ambition; Maybe. Time will tell.