Metal 3D printing is already a multi-billion dollar global industry. The additive manufacturing approach is poised to disrupt many aspects of manufacturing and will only continue to grow in the foreseeable future. However, technology is not homogeneous. Like plastic printing, there are many different approaches, each with their own pros and cons.

ONE new method announced this week by an MIT team prioritizes print speeds and scale (object size) over resolution. As described, the system is able to print large aluminum parts “at least 10 times faster than a similar metal additive manufacturing process.”

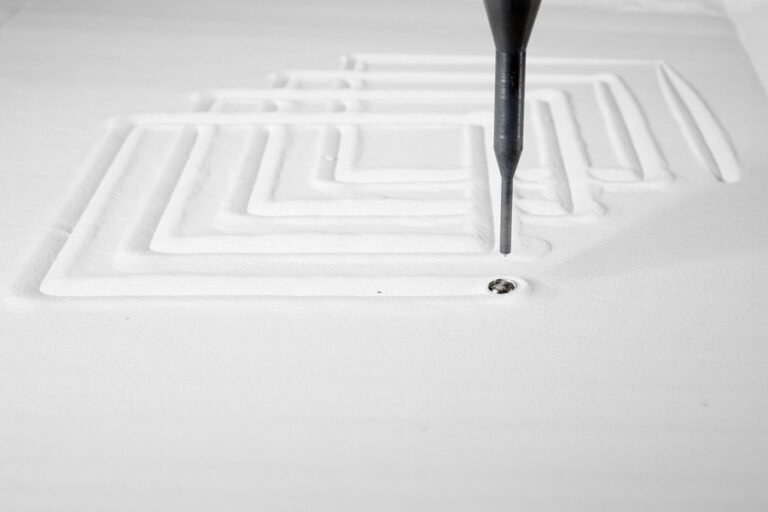

Liquid metal printing (LMP) uses a bed of 100 micron glass beads to create a structure onto which molten aluminum is deposited – a process not entirely different from injection molding. The beads are able to withstand intense heat while allowing the heat to dissipate quickly as the metal solidifies.

Since aluminum is classified as an “infinitely recyclable” material, the team behind the work envisions combining this system with a machine that melts the metal into molten form. Such a combination could prove invaluable to construction sites, bringing faster speeds and larger objects at lower costs.

Image Credits: MIT

There is, however, at least one big caveat: resolution. As evidenced in the images, the final product does not offer nearly the exact accuracy of some other methods. The resulting metal objects are bumpy and uneven, resembling the product of fused deposition modeling (FDM), which extrudes plastic layer by layer. Aluminum can, of course, be sanded, although this is probably additional time and money that most people will not want to introduce into the process.

“Liquid metal printing is really at the forefront of being able to produce metal parts in custom geometries while maintaining fast turnaround that you typically don’t get with other printing or forming technologies,” says Jaye Buchbinder of Emeco, a furniture company that helped fund the study. “There is definitely potential for the technology to revolutionize the way metal printing and metal forming is currently handled.”